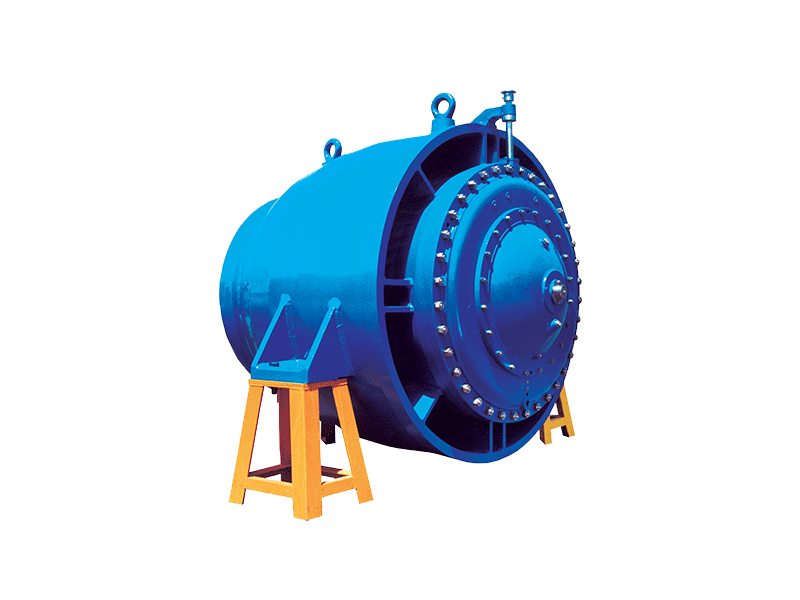

In dam application, control valves such as Hollow jet valves are installed after the butterfly valves on the outlet side. These valves always work as flow-regulating or control valves. Hallow jet valves are designed to perform regulating or control functions in water supply systems without any vibration as much as valve opening.

The Hollow jet valves are often used for the discharge into the free atmosphere. However, in some cases, the valves can be used in submerged conditions where the downstream level is above the altitude of the installation. In such cases in order to ensure proper energy dissipation, a dissipation chamber with a specific hydraulic profile is required so as to properly aerate the flow, avoiding the hydraulic instability phenomenon. Reliable and adjustable discharge of large water flows having low or high pressure requires large energy dissipation causing cavitation or excessive vibrations. The Hollow jet valve or fixed cone valve ensures very efficient control and closure and provides an economic solution for dam bottom discharge or another energy-dissipating system. The design of the Hollow jet valve ensures excellent hydraulic performance, which can be highlighted by a stable discharge. The energy dissipation is achieved with excellent conditions and ensures a symmetrical flow.

- Home

- Mirab Group

Mirab Company

Organizational Goals

- Products

- Commercial

Global Mirab

- Support

Customer Care Unit

Technical and Engineering

Manufacture and production

- Media

Technical Media

- Contact

Human Resource

Contact Us